The Complete Guide to Pyrolysis Plants

Build a Profitable

Pyrolysis Plant

From feasibility to commissioning — powered by APChemi's 49+ commercial projects, 12+ patents, and 17+ years of pyrolysis engineering expertise.

What is a Pyrolysis Plant?

A pyrolysis plant is an industrial facility that converts organic waste materials — such as plastics, tires, and biomass — into valuable products through thermal decomposition in the absence of oxygen. The process breaks down complex polymers into simpler molecules, producing pyrolysis oil, carbon black, combustible gas, and steel (from tire feedstock).

Modern commercial pyrolysis plants operate continuously at temperatures between 400-700°C, processing 20-100+ tonnes of waste per day. They play a crucial role in the circular economy by diverting waste from landfills and incineration while producing valuable fuels and chemical feedstock.

APChemi has designed, built, and commissioned 49+ pyrolysis plants worldwide, processing over 227 million kg of waste material. Our proprietary technology achieves 2-5x capital efficiency over industry averages.

See APChemi's Pyrolysis Technology in Action

Watch how APChemi's pyrolysis and oil purification technology converts waste into valuable products.

APChemi corporate overview: pyrolysis plant technology, oil purification, and 49+ commercial projects worldwide.

Types of Pyrolysis Plants

Choose the right plant configuration for your feedstock, capacity requirements, and investment goals.

Biomass Pyrolysis Plant

Convert biomass waste into biochar for CDR carbon credits, bio-oil, and green hydrogen. The fastest-growing pyrolysis market.

Tire Pyrolysis Plant

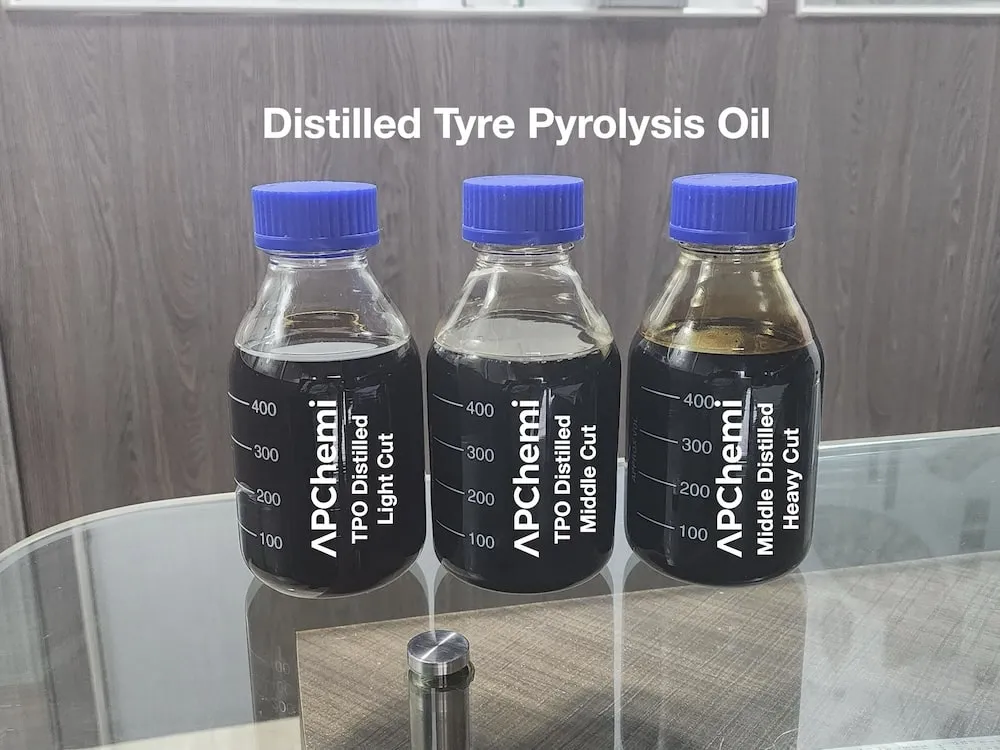

End-of-life tire recycling with APChemi's own fractional distillation for premium oil output. Produces oil, carbon black, steel, and gas.

Plastic Pyrolysis Plant

Chemical recycling of mixed plastic waste into circular feedstock and fuels via pyrolysis and oil purification.

Continuous Pyrolysis Plant

High-throughput 24/7 operation for commercial-scale waste processing. 20-100+ TPD capacity.

Batch Pyrolysis Plant

Cost-effective entry point for smaller operations. 5-15 TPD with start-stop cycles.

Pyrolysis Plant Cost Guide

Complete breakdown of costs by capacity, feedstock type, and automation level.

Ready to start your pyrolysis project? APChemi's engineers provide free feasibility assessments for projects worldwide.

APChemi's Pyrolysis Technology

Industry-leading innovations backed by 12+ patents and deployed across 49+ commercial projects.

Biochar & Carbon Dioxide Removal

Biomass pyrolysis and gasification to produce high-quality biochar for CDR carbon credits and heavy industry decarbonization.

Learn more →

Oil Purification & Distillation

PUREMAX — proprietary fractional vacuum distillation producing 62% certified biofuel content from crude pyrolysis oil.

Learn more →

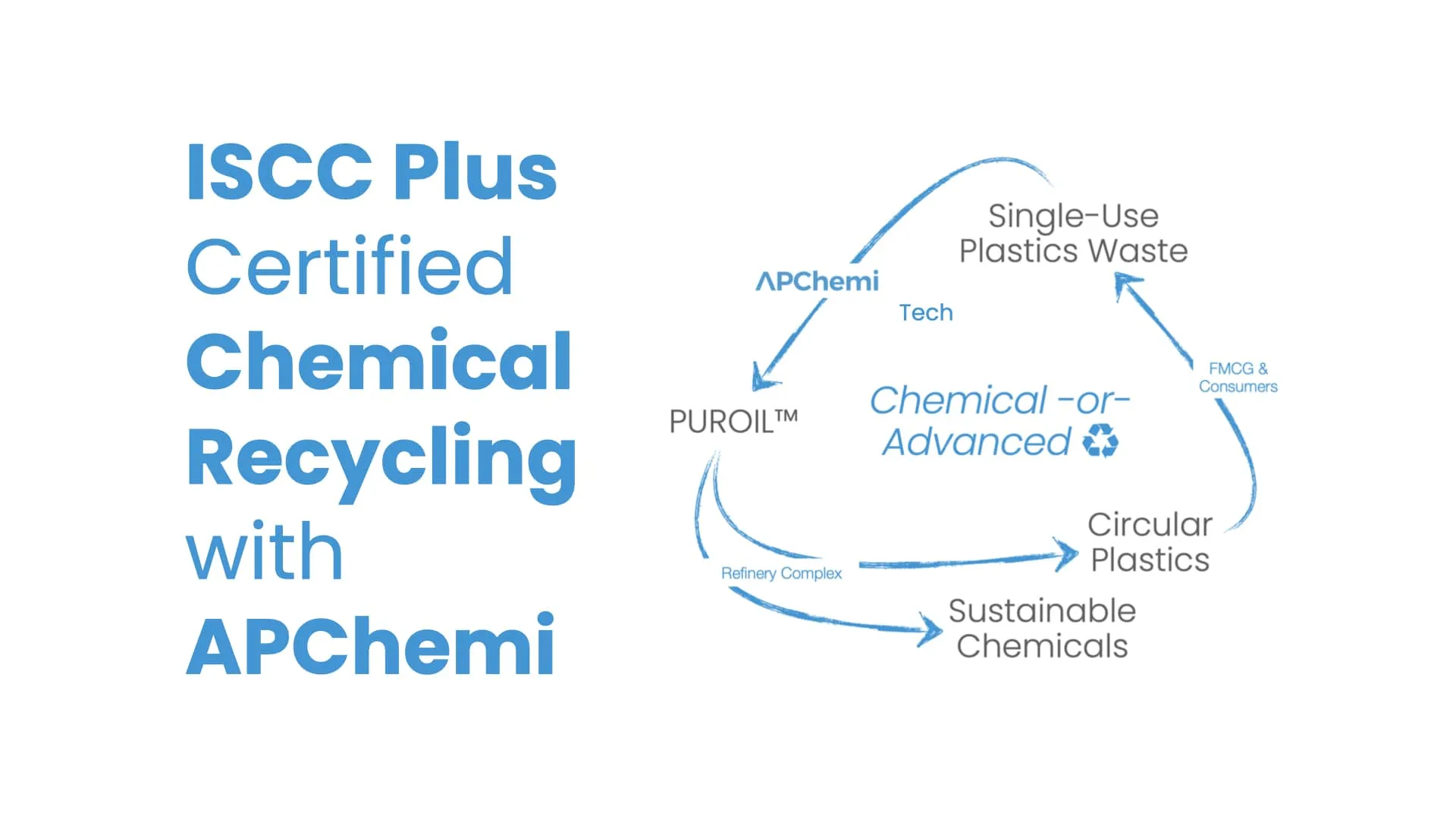

Chemical Recycling

Convert waste plastics back into virgin-quality feedstock via PYROMAX pyrolysis and PUREMAX purification.

Learn more →

Plant Troubleshooting

Expert diagnostics and optimization for existing pyrolysis plants — improve yield, uptime, and product quality.

Learn more →

Why Build with APChemi?

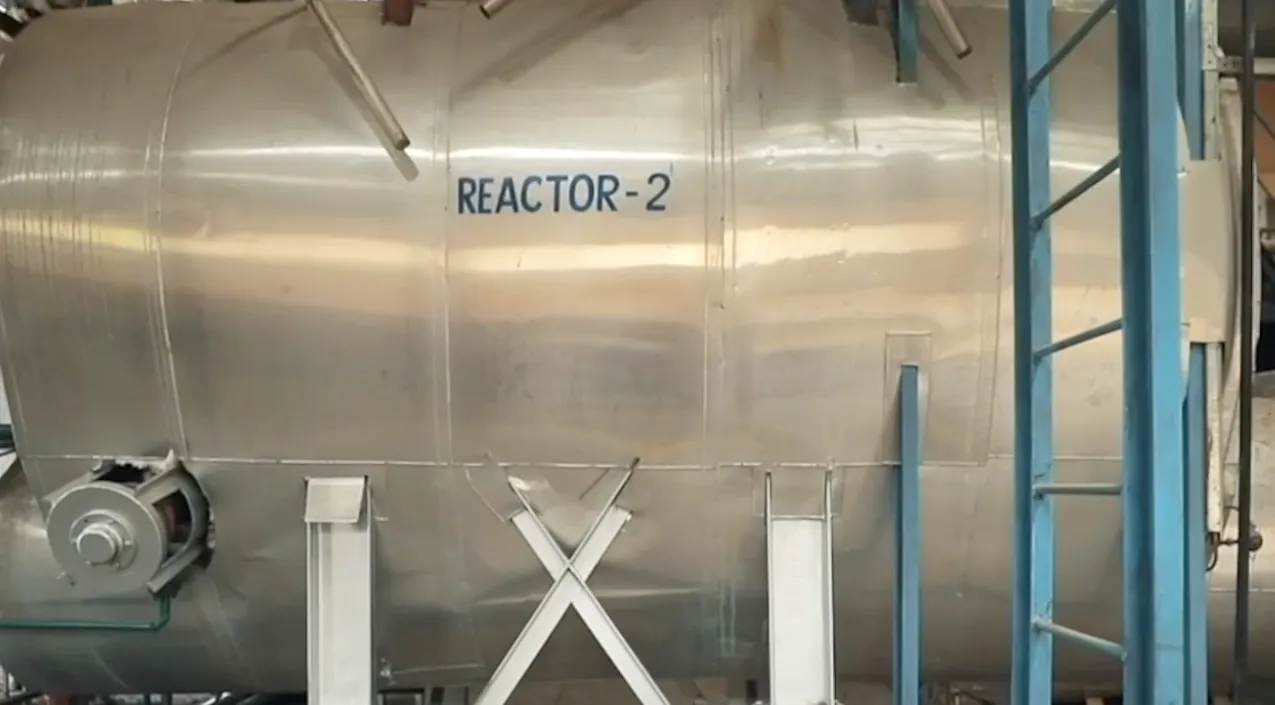

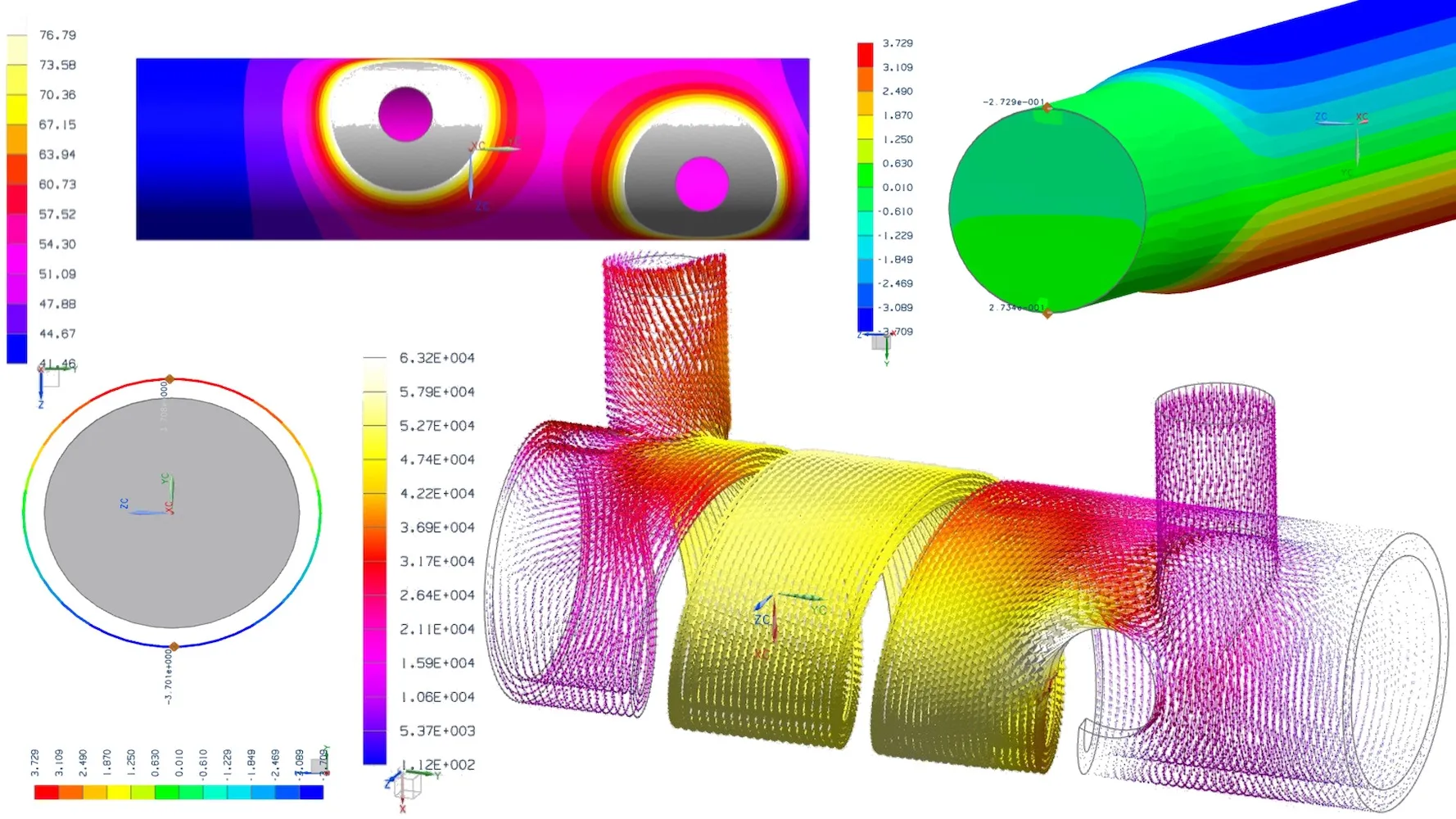

APChemi's proprietary PYROMAX reactor technology and PUREMAX oil purification system deliver 7x better pyrolysis performance across energy efficiency, safety, feedstock flexibility, cost, anti-coking, scalability, and oil purity.

49+ Commercial Projects Delivered

Proven track record across tire, plastic, and biomass pyrolysis plants worldwide — more than any specialist firm.

12+ Patents in Pyrolysis Technology

Proprietary PYROMAX reactor and PUREMAX purification innovations protected by granted patents.

Own Distillation & R&D Facility

APChemi operates its own 15,000 L/day fractional distillation plant and dedicated pyrolysis R&D lab — we test and validate before you build.

ISCC Plus Certified Plants

3+ plants with ISCC Plus certification — enabling premium pricing for circular feedstock.

2-5x Capital Efficiency

Data-driven PMC that reduces CAPEX/OPEX by up to 30% and maximizes return on investment.

330 Days Annual Uptime

Engineered for 90%+ availability with automated operation and scheduled maintenance cycles.

What Our Clients Say

APChemi ensured smooth pyrolysis plant delivery, commissioning, and assisted in raising additional funds for business expansion. Plant is operational since 2018. Our plant is ISCC Plus Certified.

APChemi offered exceptional service, reliable technology, and commitment to customer satisfaction. Plant is operational since 2018.

APChemi Exceeded expectations with pyrolysis technology and providing exceptional engineering support. We are operating APChemi's plants since 2014. Our plant is ISCC Plus Certified.

Contact APChemi for verified testimonials and reference plant visits.

Pyrolysis Plant Guides

Free resources to help you plan, finance, and build a successful pyrolysis project.

Plant Cost Guide

Detailed cost breakdown by capacity, feedstock type, and automation level.

ROI Calculator

Interactive tool to estimate returns on your pyrolysis investment.

Feasibility Study

Everything you need to assess for a viable pyrolysis project.

Business Plan Guide

Structure a bankable business plan for investors and lenders.

Choosing a Manufacturer

Evaluation framework, red flags, and regional comparisons to find the right partner.

Plant Design Guide

5 design phases, key parameters, and plant layout best practices.

Environmental Impact

Lifecycle analysis, carbon credits, and ESG metrics for pyrolysis projects.

Frequently Asked Questions

Quick answers to the most common pyrolysis plant questions.

Pyrolysis plant costs range from $200,000 for a small 5 TPD batch unit to over $5 million for a large-scale 50+ TPD continuous plant. The total investment depends on capacity, feedstock type, automation level, and whether oil purification/distillation is included. See our complete pyrolysis plant cost guide for detailed pricing by capacity, type, and region.

Pyrolysis is a thermochemical decomposition process that breaks down organic materials (plastics, tires, biomass) at elevated temperatures (400-700°C) in the absence of oxygen. The process converts waste into valuable products: pyrolysis oil, carbon black, steel (from tires), and combustible gas. It is a key technology in chemical recycling and the circular economy.

Batch pyrolysis processes one load at a time with start-stop cycles, suitable for smaller operations (5-15 TPD). Continuous pyrolysis feeds material and extracts products non-stop, achieving higher throughput (20-100+ TPD), better energy efficiency, and more consistent product quality. Our cost guide includes a detailed batch vs continuous comparison table.

Pyrolysis oil has multiple applications: as industrial fuel (replacing heavy fuel oil), as feedstock for steam crackers to produce new plastics (circular economy pathway), as a blending component for marine fuels, and after further refining, for diesel and naphtha production. ISCC Plus certified pyrolysis oil commands premium prices in the circular plastics market. See our oil purification page for details on upgrading crude pyrolysis oil.

Pyrolysis plants can process various organic waste: end-of-life tires, mixed plastic waste (PE, PP, PS), biomass and agricultural waste, waste windmill blades, rubber waste, and used oil. Each feedstock type requires specific reactor design and operating parameters for optimal yield. APChemi has experience with all major feedstock categories across 49+ delivered projects.

A complete pyrolysis plant project takes 12-24 months from feasibility study to commissioning. This includes 2-3 months for feasibility and design, 6-12 months for manufacturing and procurement, 3-6 months for installation and commissioning, and 1-2 months for performance testing. APChemi's project management consultancy ensures on-time delivery.

Key criteria: proven commercial-scale references (not just lab/pilot), relevant patents and technology IP, ISCC Plus or similar certifications, project management experience, after-sales support capability, and financial stability. Red flags include lack of operational reference sites, unrealistic yield claims, and no process guarantees. Read our comprehensive manufacturer evaluation guide for a systematic framework and regional comparison.

Required permits typically include: environmental impact assessment, air emissions permit, waste processing license, building permits, fire safety clearance, and operational permits. Requirements vary by country and region. APChemi's project management consultancy includes full regulatory guidance and permit application support. Our feasibility study guide also covers the permitting timeline.

Start Your Pyrolysis Project

Tell us about your project and APChemi's engineers will provide a free consultation within 24 hours.